MIL-STD-810 Shaker Test

What is MIL-STD-810 shaker test

The purpose of the MIL-STD-810H shaker test method is to evaluate the function and durability of the system during and after it is subjected to strong vibration and vibration to ensure that it can continue to operate under its exposure, and is usually tested using vibration shaker machine, such as electro vibration shaker or modal shaker. The MIL-STD-810 test is used by the U.S. military to test product limitations and capabilities that a product will experience throughout its life cycle, and is also used as a standard for rugged commercial products.

Common test methods for MIL-STD-810

MIL-STD-810 - the "Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Testing" - covers most of the environmental factors encountered by military equipment during use at all stages of its service life. MIL-STD-810 testing involves replicating these conditions in a controlled laboratory environment by using temperature, humidity, shock, vibration, acceleration, and other simulation devices.

Method 501.6 High Temperature

Method 502.6 Low Temperature

Method 503.6 Temperature Shock

Method 505.6 Solar Radiation

Method 507.6 Humidity

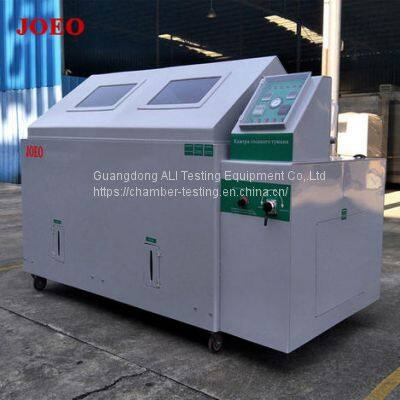

Method 509.4 Salt Fog (Spray/Corrosion)

Method 514.7 Vibration

Method 516.7 Shock

Method 520.4 Temperature,Humidity,Vibration and Altitude

Method 528.1 Mechanical Vibrations of Shipboard Equipment

Procedure for vibration method 514

There are four procedures in this method that can be used for vibration testing:

Procedure I - General vibration is used to evaluate equipment to be transported or deployed for ground vehicles, fixed-wing aircraft or rotary-wing aircraft.

Program II - Bulk Cargo Transport replicates the vibration and shock environment of military vehicles as equipment for transporting bulk cargo over rough terrain. This process is performed on a packaging tester that applies a circular synchronous motion of 5 Hz on a vertical axis.

Procedure III - Large assembly transport is carried out with vehicles on test surfaces that represent the intended operational or transport phase in the life cycle of the test project. These test sites are located at specific defense facilities, such as the U.S. Army's Aberdeen Test Center.

Procedure IV - Assembled aircraft Storage Fixed Transport and free flight uses a laboratory shake table to replicate the vibration stresses encountered during flight when equipment designed for under-wing deployment is attached to the aircraft and released.

Vibration test parameter control strategy

Acceleration input control strategy.

The vibration excitation is controlled within the specified range by sampling the vibration motion of the test item at all specific locations. These locations may be at or near the fixed point of the test item (controlled input) or the defined point on the test item (controlled response). Vibration motion can be sampled at a single point (single point control) or at multiple locations (multi-point control). The control policy will be specified in the test plan. However, it should be noted that it may be affected by the following factors: the results of preliminary vibration measurements of materials and fixtures; Considering the possibility of frequency drift, the frequency must be constantly adjusted to ensure the maximum response when conducting a fixed frequency sinusoidal "resonant residence" test. There are two methods :

a search for the maximum dynamic response;

b Maintain the phase between the control and monitoring points.

Single Point Control Option

option can be used when the preliminary vibration survey indicates a rigid vibration fixture, or when one control accelerometer accurately represents an average of the inputs at each fixing point. However, given the increased risk associated with transducer or instrumentation failure and/or calibration or scaling error attributable to a single channel, this option is not recommended. A single control point is selected:

a. Either from among the fixing points;

b. Or, in such a way that it provides the best possible solution for achieving the tolerances at the fixing points.

Multiple Point Control (average) Option

This option can be used when preliminary vibration measurements show that the input to the test item varies greatly between fixed points. Control points, usually two or three, however,

a.Random control will be based on the average of the ASD of the selected control point.

b. The sine will be based on the average of the peak response values of the selected control point.

Force control strategy

Dynamic force gages are mounted between the exciter/fixture and the test item. Exciter motion is controlled with feedback from the force gages to replicate field measured interface forces. This strategy is used where the field (platform/materiel) dynamic interaction is significantly different from the laboratory (exciter/test item) dynamic interaction. This form of control inputs the correct field-measured forces at the interface of the laboratory vibration exciter and test item. This strategy is used to prevent overtest or undertest of materiel mounts at the lowest structural resonances that may otherwise occur with other forms of control.

Acceleration limit strategy

The monitoring sensor (usually an accelerometer or strain gauge) is located at these points and uses the test item mounting point accelerometer signal to control the shaker to excite the test item, making experimental modifications to the input criteria as needed to limit the response of the monitoring sensor to a predefined limit. Changes to the specified input criteria are limited in frequency bandwidth and level to the minimum necessary to reach the required limits.

Acceleration response control strategy

Vibration criteria are specified for specific points on, or within the test item. Control accelerometers are mounted at the vibration exciter/fixture interface. Monitoring accelerometers are mounted at the specified points within the item. Low level vibration, controlled with feedback from the control accelerometers is input to the test item. The input vibration is experimentally adjusted until the specified levels are achieved at the monitoring accelerometers. This strategy is commonly used with assembled aircraft stores where store response to the dynamic environment is measured or estimated. It is also applicable for other materiel when field measured response data are available.

JOEO vibration shaker machine Test Laboratories provides knowledgeable and experienced military standard testing services to assess the durability of products against typical environmental challenges and use, and products tested to military standards are proven to withstand shock, vibration, humidity levels, and temperature changes encountered during typical use, transportation, and storage.

JOEO vibration shaker machine meets applications that require:

Perform Sine Test above 70g peak

Sine/Random Force (kN) : 1kN ~ 600kN

Acceleration (Sine/random) (g):30g~100g

Perform different mixed mode tests (sine plus random, random plus random, sine plus random plus random)

The system is suitable for compliance with the widely accepted MIL-STD-810 standard.

Recently Posted

-

ASTM D1654 Standard Test Method for Evaluation of Painted or Coated Specimens

March 4, 2024What is ASTM D1654 standard? Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Enviro Read More

Read More -

Generator Set Testing with walk in high and low temperature test chamber

November 1, 2023JOEO High Low Temperature test chamber (walk in climate chamber/walk in chambers) from ALI Testing Equipment co for High temperatu Read More

Read More